- 山东迈兰德机械设备有限公司

Industry information

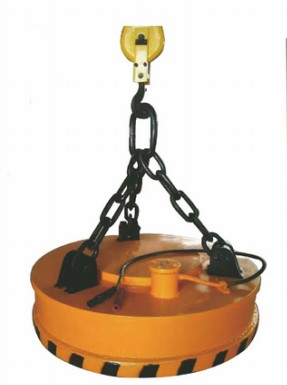

How to choose a high quality electromagnet

The quality of high-frequency magnetic chucks depends first on the product's function, service life, materials, and after-sales service. As for where to produce high-frequency magnetic chucks? This is the benevolent see the wise and see wisdom, but must remember, buy any products must choose regular manufacturers, do not go to some small workshops to buy, quality is not guaranteed, do not say, after sale In the future, there are many people who are angry. Many customers are asking why the same high-frequency disks are not the same price. There are two reasons: one is that the equipment is really good value for money, and the other is that the production cost of the equipment itself is high. As the saying goes, a penny is worth the goods, so it is said that in terms of equipment, it is not only better than the price. There is no manufacturer who sells the goods without profit. The most important thing is that we buy the equipment for the sake of Helping us make money, it’s more important to use it later than anything else! Next, teach you how to choose a high-quality high-frequency magnetic chuck -

The use of high-frequency magnetic chucks is mainly for scrap steel, milling machines and planers. The quality of them is very concerned. Once the quality of electromagnetic chuck manufacturers is not good, quality problems will affect the sales of the entire enterprise chain. Therefore, the quality of the electromagnetic chuck produced by regular manufacturers is also worthy of everyone's priority. The electromagnetic suction cups of regular manufacturers will pass the suction test. After the inspection of suction, control cabinets and lines, the quality of the equipment will be verified and sold. The after-sales service is currently The sword of competition from large manufacturers is a foundation for the development of our company for our Jiangshan Heavy Industry Machinery. It is our goal of continuous advancement.

High frequency magnetic chuck use:

1. It is mainly used for lifting magnetic materials such as steel in metallurgy, mining, casting, machinery, transportation and other industries.

2, mainly used to lift scrap steel scrap, iron, steel balls and the like (lifting equipment, forklifts, excavators, truck cranes, car cranes, dock cranes, etc.)

Features:

1. It adopts full-sealed welded structure, and the bottom is equipped with moisture-proof material, which has good moisture resistance.

2. Reasonable magnetic circuit design, high-quality low-carbon steel plate, high-quality mica with good heat conduction and heat resistance, which improves the working efficiency of the lifting electromagnet.

3. The excitation coil is optimized and specially processed to improve the electrical and mechanical properties of the coil.

4. The rated energization rate of the high-frequency lifting electromagnet is up to 75%, which improves the efficiency of the lifting electromagnet.

5. The high-temperature lifting electromagnet adopts a unique heat insulation method to increase the temperature of the object to be heated to 700 ° C, which expands the applicable range of the lifting electromagnet and the heat resistance level of the insulating material can reach C level.

6, easy to install and maintain.