- 山东骏腾起重设备有限公司

Industry information

Typical applications for aluminum alloy rails in the automotive industry.

With the development of the automobile manufacturing industry, more and more factory and enterprise workshops will use their own lightweight products to ensure more functions and higher safety and handling performance. Automotive manufacturing generally includes stamping, welding, painting and final assembly. Large core technology, as well as some other auto parts production, in the whole vehicle manufacturing, basically every part of the link will use aluminum alloy track with intelligent hoist, which can greatly improve production efficiency and reduce labor intensity.

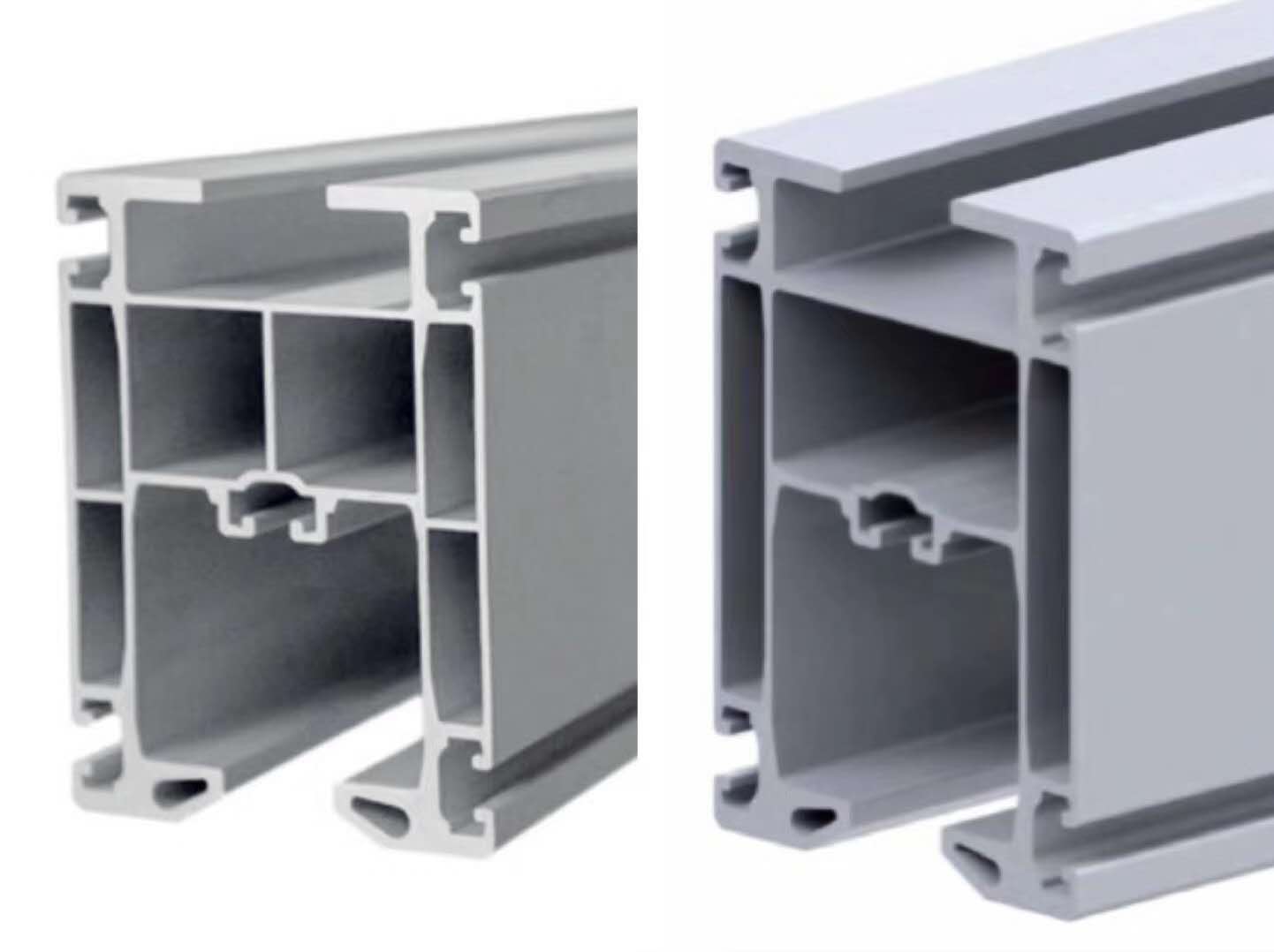

The aluminum alloy track is a lightweight material suspension conveyor system that can transport workpieces between two stations or one work area very conveniently. The aluminum alloy track is a multi-functional modular system with various installation forms for safety and simplicity. The concept of high efficiency and energy saving provides solutions for material handling, workpiece handling and assembly, which better explain the safe, comfortable and smooth operation experience.

The advantages of aluminum alloy track applications in the press shop, welding shop, painting shop, assembly shop and other auto parts production lines are:

1. The aluminum alloy track is made of aluminum alloy material, which is light in weight, strong in carrying capacity and easy to install;

2, higher hardness than ordinary steel track, corrosion resistance, wear resistance, drag resistance, drag and effort, low noise;

3, the load has 250kg, 500kg, 750kg, 1200kg, various forms to meet the needs of different loads and stations.